Energy dispersive X-ray fluorescence (EDXRF) spectroscopy is a rapid and non-destructive elemental analysis technique. It helps food labs optimize production processes and minimize downtime. EDXRF is used to measure nutrients and fortificants, screen for contaminants and incidental adulterants, and identify foreign body contaminants found during production or packaging.

EDXRF performs measurements on all kinds of samples including liquids, solids, or loose powders. It combines high accuracy and precision with minimal sample preparation. It provides simultaneous analysis of elements from carbon to americium and for elemental concentrations from ultra-trace levels up to 100 percent, depending on the specific instrument configuration.

EDXRF is a powerful, green alternative to traditional atomic spectroscopy methods. Sample preparation is rapid and non-destructive with no hazardous waste disposal regulations to be concerned with. Additionally, EDXRF has comparatively low operation or maintenance requirements and costs.

Options of this type of spectroscopy include the following.

- Benchtop EDXRF is the food lab method of choice for dedicated applications in quality and process control with its ease of use and compact size. It delivers speed and analytical flexibility for a multitude of research and monitoring tasks.

- Micro-XRF is the food lab method of choice for high-speed, two-dimensional elemental analysis of non-homogeneous or irregularly shaped samples as well as small samples or inclusions.

- Total reflection XRF (TXRF) spectrometry is the food lab method of choice for rapid ultra-trace elemental analysis, and low parts-per-million (ppm) and parts-per-billion (ppb) of multiple sample types.

- Handheld XRF (HHXRF) is the food lab method of choice when an analyzer needs to be brought to the sample for immediate analysis rather than transporting the sample to the lab.

Analysis of Elemental Nutrients and Fortificants

Benchtop EDXRF analyzers quickly measure elemental nutrient and fortificant content in food products at any stage of production, from incoming raw materials to end products. This includes elemental additives such as sodium and potassium or fortificants such as iron and calcium in milk products. EDXRF also measures elemental nutrient content such as selenium and molybdenum in dietary supplements or magnesium and iron in animal feed.

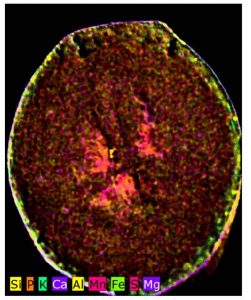

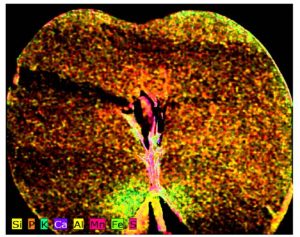

Micro-XRF goes one step further by providing visual images of the nutrient or fortificant distribution on or within the food product. A slice of produce is measured to determine elemental nutrient rich locations, such as in bananas and apples. Micro-XRF also provides elemental fortification distribution maps of crackers, chips, or cereal to help optimize food processing. Mapping images for the distribution of phosphorus, sulfur, and iron on cereal as well as salt distribution on snacks help determine effective fortification process steps.

Analysis of Incidental Adulterants and Contaminants

Figure 3. Elemental nutrient distribution analysis of apple slice with laboratory micro-XRF.

Image Credit: Bruker

EDXRF is ideal for routine analysis of incidental adulterants and contaminants in foods at any stage of the product. These efficient analyzers quickly identify and quantify incidental adulterants such as lead or chromium from colorants, mercury or copper from fungicides, lead from water, or arsenic and bromine from pesticides. Minimal sample preparation is required to achieve high precision and accuracy of results.

TXRF is best suited for ultra-trace elemental analysis. While it is a powerful tool for food fraud prevention in globalized supply chains, it’s particularly relevant for food safety as outlined by the Food & Agriculture Organization/World Health Organization (FAO/WHO) standards, stating it can directly analyze low levels of arsenic in rice or lead in tea drinks. Its versatility for the analysis of multiple sample types as well as minimal sample preparation requirements for even complex samples makes it much faster than inductively coupled plasma emission spectroscopy, which requires fully dissolved liquid samples for analysis.

Identification of Foreign Body Contaminants Found

Contaminants are the last thing anyone wants in their final products, but with virtually non-stop use of production line equipment such as food augers, roller mills, air locks, and drying conveyors, it happens. When contaminants are found, the use of handheld XRF can help food labs quickly identify the foreign body and find its source to fix the problem before any more product is contaminated.

ACCESS THE FULL VERSION OF THIS ARTICLE

To view this article and gain unlimited access to premium content on the FQ&S website, register for your FREE account. Build your profile and create a personalized experience today! Sign up is easy!

GET STARTED

Already have an account? LOGIN