Editor’s note: This is part one of a two-part series focused on dust hazard analysis. In this article, we focus on the dust hazard analysis process. In part two, we take a look at how to put the analysis into practice at your food plant.

Confused about the dust hazard analysis (DHA) process? You’re not alone. Many bakers and food processors have questions about DHA requirements. Here’s what you need to know and how to get it done.

Why Do You Need a Dust Hazard Analysis?

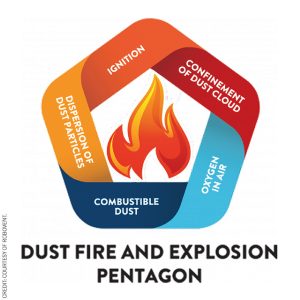

A DHA is required for facilities that handle combustible dust, which includes most food processing facilities. Dry food dust—including dust from sugar, flour, starches, cocoa powder, dry spices and flavorings, dehydrated milk products, and dust from processing grains and nuts—is combustible under the right conditions. These conditions include:

- Suspension of dust in the air in a cloud;

- Confinement of the dust cloud in an enclosed space, such as a storage silo, enclosed conveyor system or mixer, or dust collection system);

- Oxygen to fuel a combustion reaction (e.g., oxygen found in atmospheric air); and

- An ignition source, such as an open flame or high heat from ovens, sparks from friction in mechanical systems or conveyors, or static electricity.

Under the National Fire Protection Association (NFPA) standard 61, “Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities,” Chapter 7.1.2.2, a DHA is required for bakeries and food processing facilities every five years. A new analysis may also be required if the facility introduces new dust types, processes, or equipment that will substantially change the risk profile.

The DHA Process

NFPA 61 requires that “the DHA shall be led by a qualified person.” For most food processors and bakeries, that will mean getting outside help from an expert to complete the process. The organization does not mandate a specific format for the DHA but, in general, the process will include the following:

- Material characterization;

- Process characterization and hazard identification;

- Evaluation of existing safeguards;

- Mitigation recommendations; and

- Verification.

Material Characterization

The first step in the DHA process is to determine the material characteristics of the dust. In some cases, it may be possible to use published industry values for your dust type; however, your dust must be substantially similar to the dust used for comparison in the published values. The explosibility of dust is dependent not only on its chemical composition but on factors such as particle size distribution, particle morphology, moisture content, and other variables. For this reason, it is usually advised that facilities collect a sample of their specific dust for analysis. The sample must be sent to an independent accredited laboratory (ISO17025 Accredited Lab or Calibration Round Robin Lab) and tested using NFPA-approved analytical processes covered by the accreditation. You can find an accredited laboratory at dustsafetyprofessionals.com.

Testing may include all or some of the following:

- Go/no-go testing: A simple screening test to determine whether dust will ignite in a pile and/or explode in a cloud.

- Explosion severity testing: These tests are conducted in a pressure vessel to determine the explosion indices, measures of how severe an explosion would be if one were to occur. These indices include KST (the speed of pressure rise) and Pmax (the maximum pressure rise in a closed vessel).

- Additional explosion testing: Other testing may include indices such as minimum explosive concentration (MEC), minimum ignition energy (MIE), and minimum ignition temperature (MIT). These values provide insight into the specific conditions under which an explosion is likely to occur.

Process Characterization and Hazard Identification

The DHA will also include measurement of pre-mitigation conditions, analysis of the processes in the facility, and identification of specific hazards. For example, it can pinpoint:

ACCESS THE FULL VERSION OF THIS ARTICLE

To view this article and gain unlimited access to premium content on the FQ&S website, register for your FREE account. Build your profile and create a personalized experience today! Sign up is easy!

GET STARTED

Already have an account? LOGIN