(Editor’s Note: This is an online-only article attributed to the August/September 2017 issue.)

On April 17, 2017, a family from Virginia found an unappetizing item in their bagged ready-to-eat salad. On the bottom of a plastic bag, they discovered a chopped-up corpse of a mouse stacked between savoy cabbage leaves and carrot slices. Shocked and outraged, the family sued both the food company responsible for rodent-contaminated salad production and the retailer distributing this product.

This is only one albeit a very impressive example of what can happen if food contaminants haven’t been detected and eliminated timely. According to the statistics, microbiological and physical contamination together are responsible for 54 percent of recalls in the food industry. And, while a recall is somewhat better than a lawsuit, it still causes losses, so it is essential to detect and discard contaminated products as early as possible.

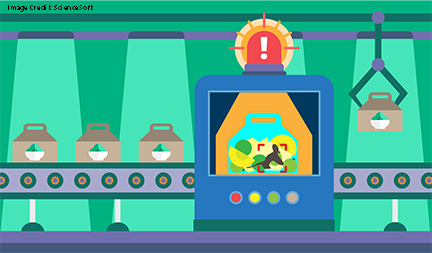

What can food companies do to detect foreign objects in their products at different production stages? One of the most reliable options is automated visual inspection (AVI) of food.

Assuring Quality

An AVI system usually consists of image-capturing equipment and image-analysis software. AVI is based on the technology that is called machine vision because it allows machines to “see” and analyze real-world objects. An AVI system always includes a lighting source, a camera or another sensor (depending on the spectral range), and a processing unit. The software part is a set of image analysis algorithms that sift an image in order to detect any defects or deviations in the product’s appearance.

The AVI software analyzes an image in the following steps.

- Preprocessing. The software removes unnecessary noise and enhances image quality to optimize it for further processing.

- Extraction of information. Image analysis algorithms separate the image into meaningful regions (segmentation) and detect important features (feature extraction).

- Decision-making. The software detects and classifies objects in the image and then makes a decision on the actions required (in the simplest case, accepting or discarding a product). This step is performed by state-of-the-art machine learning algorithms: convolutional neural networks, support vector machines, k-nearest neighbors, etc.

It is worth noting that all this happens within seconds or even fractions of a second. This processing speed is one of the major reasons why AVI is considered more efficient than any manual inspection technique. Other reasons include the properties of software—it’s tireless, consistent, unbiased, and accurate. Besides that, the “visible spectrum” of machine vision is five times broader than that of a human and includes infrared, X-ray, and UV ranges.

In the Food Industry

AVI is used in many industries, and the simpler and more standardized an inspected object is, the more inspection accuracy can be achieved. In the food industry, it assures that the product meets certain quality criteria: size, shape, freshness (in some cases), absence of surface defects, and, of course, absence of foreign objects. Besides simple quality assurance (pass/fail test), an AVI system can grade the products and sort them into several classes depending on their quality.

Looking for Foreign Objects

Depending on the inspected product, physical food contaminants can be detected either by optical inspection (in the visible light) or by X-ray examination. Optical inspection detects foreign objects among fruits, vegetables, berries, nuts, and grains. It can also estimate fecal contamination of poultry and thus indirectly assess its microbiological contamination. X-ray examination is used to detect foreign objects in packaged products, for example, parasites in fruits and vegetables, bone fragments left behind in the de-boning process in poultry, etc.

In the dead mouse case described above, an AVI system could have detected foreign parts among the leaves and vegetables before they were packed. Alternatively, an X-ray-based system could have inspected already sealed plastic bags, although at this stage the scrap cost would be higher. Nevertheless, a fully automated food production process would have benefited from equally automated quality inspection.

And More

By employing a visual inspection system for quality check of its products, a food company not only reduces the losses, but also substantially decreases the chance of a quality-related scandal. Many tiny but still important issues can be revealed in the production of food (larvae in apples, mixed grains, pits and leaves, bone fragments, etc.).

ACCESS THE FULL VERSION OF THIS ARTICLE

To view this article and gain unlimited access to premium content on the FQ&S website, register for your FREE account. Build your profile and create a personalized experience today! Sign up is easy!

GET STARTED

Already have an account? LOGIN