According to the World Health Organization, there are 600 million cases of foodborne diseases that lead to 420,000 deaths worldwide each year. Proper hand hygiene is an important and effective way to prevent cross-contamination in a food processing facility. Contaminated hands can transfer germs to surfaces, utensils, office supplies, telephones, door handles, and other items commonly touched, making hand hygiene the first line of defense to prevent cross-contamination.

Here, we look at several techniques for good employee hygiene in the food plant setting.

Personal and Hand Hygiene

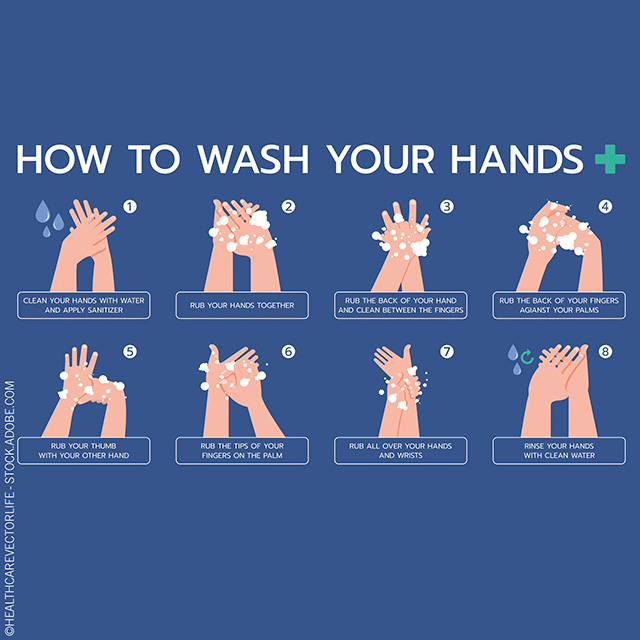

Practicing proper hand washing techniques is a good way to reduce bacteria on hands. The Centers for Disease Control and Prevention (CDC) guidelines for proper hand washing technique are as follows: Thoroughly wet hands with clean, running water, apply an adequate amount of soap, rub palms and backs of hands, rub thumbs and interlace fingers, rub fingertips into palms of opposite hands, and rub wrists.

The actual hand washing portion should last 20 seconds to ensure effective cleaning. Rinse well with running water and dry hands thoroughly with a disposable paper towel. For maximum results, sanitize hands after they’ve been properly washed to further reduce the presence of pathogens on the hands. The goal of hand hygiene is to reduce the number of pathogens on the hands to the smallest number possible, making hand sanitizing a crucial part of the process.

When choosing soap, choose a quality hand soap that won’t dry out employee hands and, preferably, choose a sanitizing hand soap designed specifically for food processors. Choose an E2-rated, fragrance and dye-free hand soap formulated with emollients to keep skin soft and healthy. Sanitizing with a quality alcohol-based hand sanitizer after handwashing will further reduce germs on the hands. An atomized spray saturates fingernails, cuticles, cracks and crevices of the fingers and hands, where pathogens commonly hide.

Footwear Sanitation

In addition to practicing proper hand hygiene, implementing more personal hygiene best practices, such as a footwear sanitation program can help reduce pathogens in a food processing environment. A footwear cleaning and sanitation program is important for food processing facilities because employees can bring pathogens into critical control areas through contaminated footwear. Without a dedicated footwear cleaning and sanitation program, food production facilities are at risk of workers bringing contaminants into their facilities and possibly contaminating product. Footwear should be cleaned prior to sanitization to remove any dirt or debris on the bottoms or sides.

A successful footwear hygiene program should be customized to fit a facility’s specific needs, making it crucial for food processors to choose the equipment best suited for their facility. Footwear should be properly cleaned using a boot scrubber or some other method that effectively removes debris. Once footwear is cleaned, food production workers can move on to a footwear sanitation station for maximum pathogen reduction. Adding a walkthrough footwear sanitizing unit helps reduce cross-contamination. Unlike traditional footbaths, a footwear sanitizing unit provides more consistent results because it provides each worker with a fresh dose of sanitizer; there is no need for constant monitoring. Traffic flow can be designed to eliminate the possibility of workers avoiding the units, and the unsightly visual of a messy foot bath is replaced with a clean, effective piece of equipment.

Training Employees for Proper Sanitation

When training employees on hand hygiene, it’s important to implement a training program that presents the how, when, and why of proper hand hygiene. Using an expert to conduct the training and demonstrate correct hand washing techniques is crucial. In addition, demonstrations and Q&A sessions can help make the training more dynamic and interesting. A written quiz at the end of the training helps evaluate the trainee’s knowledge and readiness. As with any training, refresher training courses are important to help improve the effectiveness of the initial training.

ACCESS THE FULL VERSION OF THIS ARTICLE

To view this article and gain unlimited access to premium content on the FQ&S website, register for your FREE account. Build your profile and create a personalized experience today! Sign up is easy!

GET STARTED

Already have an account? LOGIN